ENGINEERING AND MINING EXPERIENCE

Examples of SION’s engineering and mining experience include, but are not limited to, the following:

Barrick Goldstrike Mines,

Elko, Nevada

Engineering services including fabricating a pump platform in an AA freshwater ponds and providing structural steel and platform solutions regarding the modification and installation of an existing eight-tank C.I.L. circuit into (two each) four-tank C.I.L. circuits.

Cobre Mining Company

Continental Mine Project

This SION project was in two phases: Phase 1 refurbished the existing mill equipment (which had been down for ten years) for start-up; Phase 2 consisted of Engineering, Procurement, and Construction Management and supply to enhance the existing equipment to bring the mill from 5000 TPD to 7500 TPD. The original circuit consisted of a jaw crusher, SAG mill, Pebble Mill, Classification, Flotation, and Filtration. SION upgraded the Classification, added to the flotation, installed a 5-1/2’ Short Head Cone Crusher along with Associated Conveyors and Structures (this Crusher broke the recirculation fraction). SION supplied a complete Surface Loadout Facility for the underground ore.

Çöpler Gold

Ilic, Turkey

SION provided the engineering and supply of a 6 tonne per day Desorption-Recovery-Regeneration plant Carbon Screening, Carbon Attrition, Electrowinning, Dore Production, Precipitate Retorting and Mercury Removal from Gaseous systems. All pipe works were designed and supplied, all electrical was designed, instrumentation was designed and assistance was supplied to the Instrumentation subcontractor. Construction Management assistance was supplied and construction assistance to complete the project was also supplied. All import and shipping logistics were supplied along with the startup and first-year spares.

Çukurdere Madencilik

Erzincan Province, Turkey

SION provided the Engineering, Supply, and Start-Up for a 25,000/tons per day Gold Recovery Heap Leach Plant

Dee Gold Mining Company

Carlin, Nevada

SION provided design, fabrication, and supply services for an expansion of milling operations and related services to expand plant capacity from 750 TPD to 1300 TPD. Work included tying in and an additional ball mill, provision of cyclones and all relevant launders, and piping to integrate the new mill into existing plant circuits.

Echo Bay Mines

Manhattan, Nevada

SION provided the Manhattan Mill Expansion Project as a turnkey package of engineering, procurement, and construction management (EPCM). The initial planning called for a 1500 TPD counter-current decantation (CCD) circuit, followed by a 1000 GPM Merrill-Crowe plant. This system was completed by the project deadline and turned over to Echo Bay Mines. Changes in parameters, initiated by the Owner, called for downsizing the process to 650 GPM; incorporation of 21 change orders added to the scope of the initial project. An 11 cubic foot mercury retort was provided for the project, in addition to the work listed above.

Hecla Mining Company

Republic, Washington

SION supplied and installed a complete CCD circuit, including five thickeners; underflow and overflow pumps; instrumentation with variable frequency drives on underflow and overflow pumps; flow and density instrumentation; all piping and electrical; building; and services including equipment design, fabrication, and construction management.

Hecla Mining Company

Sonora, Mexico

SION provided the engineering, procurement, and construction management for this 3000 TPD gold heap leach facility. The project consisted of the design, engineering, fabrication, and installation for the skid-mounted, gold recovery process plant. Systems included Adsorption Columns, Carbon Stripping System, Acid Wash System, Carbon Conditioning (including regeneration kiln), Carbon Storage, Solution Storage, Electro-winning / Re-plating equipment, Melting Furnace, Mercury Retort, Concrete Containment, and all in-plant electrical. In addition to the Process Plant, SION handled site layout and architectural design.

Hecla Mining Company

Yellow Pine, Idaho

When ore body was completely exhausted, SION disassembled and moved the complete Yellow Pine ADR processing plant from Yellow Pine, Idaho to the La Choya project in Sonora, Mexico; where it is in operation today.

Mining Corporation of Canada, Ltd.

Dubreuville, Ontario, Canada

SION contracted for the supply of the plant’s stripping system electro-winning / re-plating systems, acid wash system, and carbon regeneration. The scope of work involved design and fabrication of all system components involved, and the provision of General Arrangements, steel placement, piping, and instrumentation diagrams integration SION’s portion of the job with overall plant construction and piping design and details.

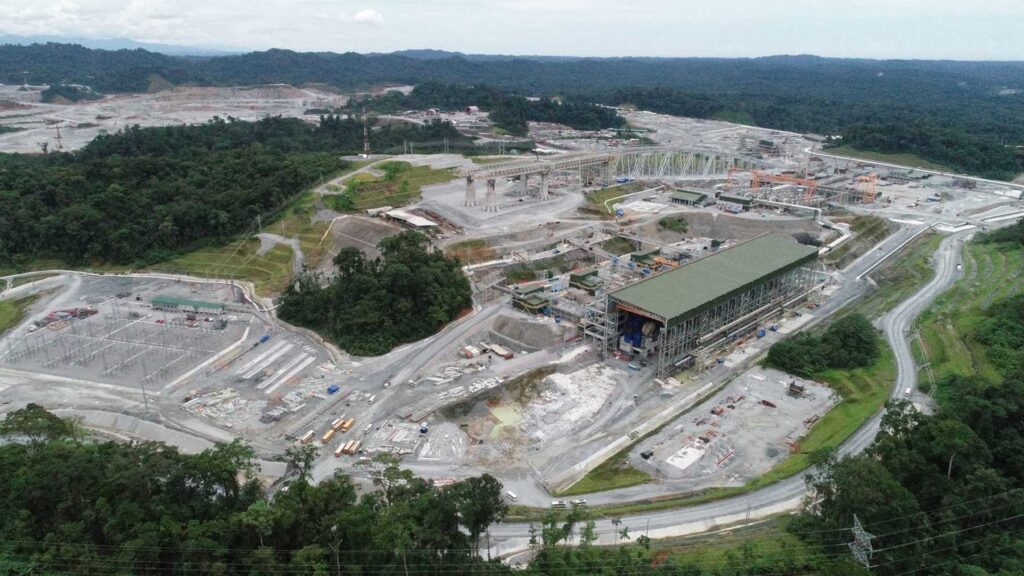

Philex Mining Corporation

Manila, the Philippines

SION provided the design and fabrication of a complete 650 GPPM skid-mounted gold recovery (carbon) process plant, including the following systems:

• Adsorption Columns

• Carbon Stripping System

• Acid Wash System

• Carbon Conditioning (including Regeneration Kiln)

• Carbon Storage

• Solution Storage

• Electro-winning / Re-plating Equipment

• Melting Furnace

• Concrete Containment Design

• All In-Plant Electrical Services

• Crushing and Agglomeration System

Rainy River

Fort St. Francis, Ontario, Canada

SION provided the engineering and supply of a 20 tonne per day CIP carbon screening, desorption recovery-regeneration plant carbon screening, carbon attrition, carbon sizing screening, and carbon fines recovery. All pipe works were designed and supplied and installed, all electrical was designed, supplied, and installed, instrumentation was designed, supplied, and installed. Construction Management assistance was supplied and assembly of the complete project was also supplied. All import and shipping logistics were supplied along with the startup and first-year spares.

Rea Mining Corporation

East Ely, Nevada

SION provided the design and fabrication of a complete 1000 GPM skid-mounted gold recovery (carbon) process plant, including the following systems:

• Adsorption Columns

• Carbon Stripping System

• Acid Wash System

• Carbon Conditioning and Regeneration Kiln

• Carbon Storage and Solution Storage

• Electro-winning / Re-plating Equipment

• Melting Furnace

• Concrete Containment Design

• All In-Plant Electrical Services

Westmont Mining Inc.

Jefferson, South Carolina

SION provided the engineering, procurement, and construction management (EPCM) for this 700 GPM skid-mounted gold recovery (carbon) process plant. The systems included the following:

• Adsorption Columns

• Carbon Stripping System

• Acid Wash System

• Carbon Conditioning and Regeneration Kiln

• Carbon Storage and Solution Storage

• Electro-winning / Re-plating of Equipment

• Melting Furnace

• Concrete Containment Design

• All In-Plant Electrical Services

This facility incorporated a Cyanide Destruction Circuit (CCD) as an integral part of the design. In addition to the process core, SION handled the crushing station, mine facilities architectural design, site layout, and construction management for the construction of all ponding, leach area, containment for environmental impoundments, and plant water systems.

Yamana Gold

Argentina

SION provided the Engineering, Supply, and Start-Up for a 15,000/tons per day Gold Recovery Heap Leach Plant.

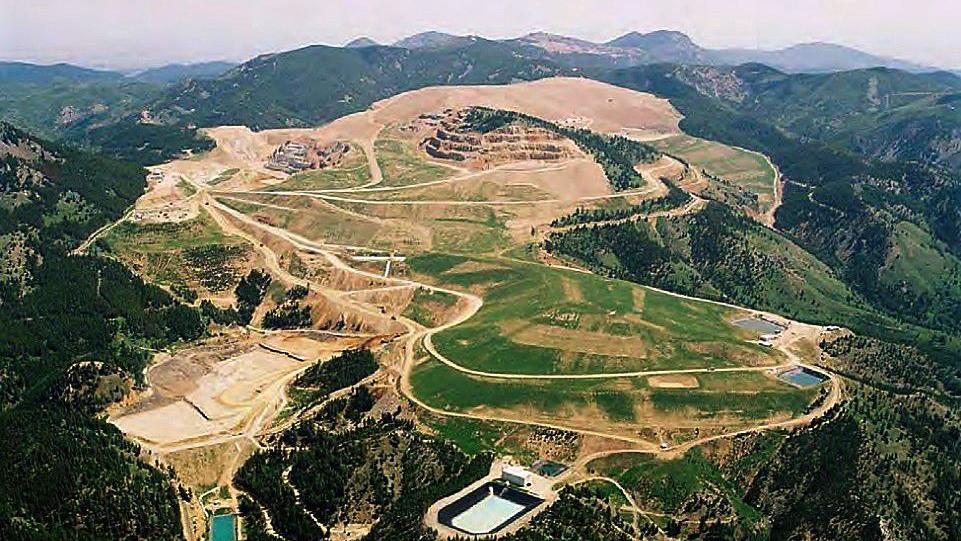

Zortman Mining Inc.

Zortman, Montana

Design and supply of solution heating system to enable the plant to extend the season for its heap leaching system and engineering and supply of a 150 PPH skid-mounted rotary carbon regeneration